|

|

|

|

��Click for zoom-in�� |

| wheel |

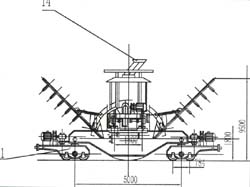

Dolly operation mechanism |

Belt conveyor |

Ingredient Belt conveyor |

Coal scuttle gate electric control equipment |

Metal structure |

Wheel(L) |

1.3m |

Motor |

type |

TDO3-160M-12/6 |

Performance |

Throughput (Q) |

1500t/hr |

Performance |

Throughput (Q) |

1500t/nr |

�ߴ� |

Gate width (B) |

400mm |

Form |

Double combination I-shape bracket |

Gauge(I) |

3m |

����(N) |

5Kw/7.5kw |

����(B) |

1000mm |

����(B) |

1000mm |

Gate height (H) |

JD3-100s-6 |

����(H) |

1.8m |

Number of wheels (n)(n) |

4 |

�D(zhu��n)��(n) |

450rpm/950rpm |

����(v) |

1.6m/s |

����(V) |

1.6m/s |

늄�(d��ng)�C(j��) |

��̖(h��o) |

1.5Kw |

����(B) |

1.8m |

ֱ��(D) |

400mm |

�Ƅ�(d��ng)�� |

��̖(h��o) |

TJ2-200 |

�C(j��)�L(zh��ng)(L) |

27.8Im |

�C(j��)�L(zh��ng)(L) |

2m |

���ʣ�N�� |

1000rpm |

���L(zh��ng)(L) |

30m |

�ٶ� |

��һ�n(V�M(j��n)) |

23.04m/min |

�Ƅ�(d��ng)����(MZL) |

16Kg-m |

늄�(d��ng)�LͲ |

��̖(h��o) |

TDY-75.2.0-80.50 |

늄�(d��ng)�LͲ |

��̖(h��o) |

JDY 40.2.0-80.32 |

�D(zhu��n)�٣�n�� |

WD-78 |

�O(sh��)Ӌ(j��)���a(ch��n)���� |

1500t/hr |

�ڶ��n(V��) |

11.19m/min |

����늴��F��̖(h��o) |

MZDI-200 |

����(N) |

15Kw |

����(N) |

4Kw |

݆�� |

��̖(h��o) |

|

������(N) |

125KW |

| ���p�� |

��̖(h��o) |

ZSC600-IV2 |

������(d��ng)��(i��) |

37.9 |

����(V) |

1.6m/s |

����(V) |

1.6m/s |

����(d��ng)�ȣ�i�� |

40 |

��������G�� |

162T |

����(d��ng)��(i) |

37.9 |

�������(JC��) |

100�� |

ֱ��(D) |

500mm |

ֱ��(D) |

320m |

������ͣ�JC���� |

100�� |

���C(j��)�Ƅ�(d��ng)��(d��o)늲��ð�ȫ������̖(h��o)HDH-1000-1250 |

|

| |

��܇�\(y��n)�ЙC(j��)��(g��u) |

��܇�\(y��n)�ЙC(j��)��(g��u) |

܇݆ |

��ʽ |

�_(k��i)ʽ |

�p���� |

��̖(h��o) |

JZQ-500-II-2Z |

܇݆ |

,܉��(L) |

30m |

.늄�(d��ng)�C(j��) |

��̖(h��o) |

YZB-160L-6 |

�_(k��i)ʽ����(d��ng)�C(j��)��(g��u) |

��� |

�A���X݆ |

ֱ��(D) |

4000mm |

����(d��ng)��(i) |

10.35 |

݆����S�� |

0.78m��5m |

����(N) |

11KWX4 |

С�X݆�X��(sh��)(ZI) |

21 |

����(sh��)(Z) |

9(�p��) |

�_(k��i)ʽ����(d��ng)�C(j��)��(g��u) |

ȡ�ϙC(j��)��(g��u)��� |

�[���݆ |

݆��(sh��)(n) |

8 |

�D(zhu��n)�� |

935r/min |

��݆�X��(sh��)(Z2) |

43 |

����� |

0.03m |

����(d��ng)��i |

12.8 |

ֱ��(D) |

500mm |

�p���� |

��̖(h��o) |

݆�p���� |

�(q��)��(d��ng)݆�X��(sh��)(Z3) |

55 |

݆��(sh��) (N) |

5.66rpm/11.3rpm |

�[���݆ᘔ�(sh��)Z1 |

10 |

�ٶ� |

��һ�n(V�M(j��n)) |

6.47m/min |

|

40 |

ģ��(sh��)(m) |

8mm |

|

����(d��ng)��(i) |

����(d��ng)�� |

72.62 |

늄�(d��ng)�C(j��) |

��̖(h��o) |

JDOC-180ZM-8/4 |

�[���݆ᘔ�(sh��)Z2 |

128 |

�ڶ��n(V��) |

14.24m/min |

�Ƅ�(d��ng)�� |

��̖(h��o) |

TJ2-200 |

������(d��ng)��(i) |

104.8 |

����(N) |

15KW/22KW |

������(d��ng)��(i��) |

129.375 |

���]�܉(P) |

43`50Kg/m |

�Ƅ�(d��ng)����(MZL) |

16kg-m |

�������(JC��) |

25�� |

�D(zhu��n)��(n) |

750rpm/500rPM |

�������(JC��) |

100�� |

****݆��(pmax) |

20T |

����늴��F��̖(h��o) |

MZDI-200 |

���M(j��n)���x 200 400mm |

|

Main technical parameters |

1��The cart and dolly running are all speed-adjusted by transducer.

2���This machine adopts the PLC program concentrated control on the reclaiming, cart and dolly running, lighting and watering, etc in the driver's room.

3��The throughput of the reclaimer is Q=1500T/HV and the span could be 32m, 28m and 25m, it could work backward and forward, from left to right and reclaim the materials from positive and negative directions at any point.

4�����If the machine is equipped with claw equipments, when the materials are piled with 45��slope, it means the normal operation; with 60��, the claw reaches the material stock first while the bucket wheel machine fails to take it, then the dolly running mechanism shall be started to take the claw off before continuous work.

5�����In order to protect the reclaiming coal tub of the bucket wheel, it shall be 50MM away from the ground.

6��Material height offside engine shall be set inside the chute of the machine, retaining switch and rubber baffle on the top of the dolly rail to prevent the aberration of the dolly. The dart frame shall be set with the retaining switch and rubber baffle too.

7���In order to prevent the seeper on the working site in rainstorm season, this equipment shall consider the solution of gate legs adjustment(SGL240-13-00).

8��The ingredient conveyor is electrically controlled on the matching flow, in the future the computer and electrical belt measure will be installed to control the mixture ratio.

9�����The metal structure of this equipment all experiences the sand spray and rust removal, spray the anticorrosive varnish once and the green primer twice.

10�������As the gate legs are adjustable, the chassis of the sliding current collector shall have the corresponding adjustable cushion coat.

11�����The rail slope control on the dart in the civil work shall be controlled within the range of 0 to 10 and the gauge error shall not be ��5MM.

12��The relative height of the upper and lower beam shall not exceed 10MM and the non- perpendicularity isH/3000, namely 0.3MM.

13��The reclaiming dart and dolly designed in this machine both have two speeds, either is available according to the operation for the convenience of the relation adjustment of charge and discharge, backward and forward.

14���The cost of the safety sliding line is not included in the whole machine. |

| |

|

|

14 |

HQL1500-30-14 |

slider current collector |

1 |

Component |

1000 |

1000 |

|

13 |

HQL1500-30-13 |

adjustable gate leg |

6 |

A3 |

1603 |

9620 |

|

12 |

HQL1500-30-12 |

dolly integrator |

1 |

Component |

5000 |

5000 |

|

11 |

HQL1500-30-11 |

rubber buffer |

4 |

Component |

100 |

400 |

|

10 |

HQL1500-30-10 |

operation room |

1 |

Component |

2850 |

2825 |

|

9 |

HQL1500-30-9 |

coal bucket electric control assembly |

1 |

Component |

1996 |

1996 |

|

8 |

HQL1500-30-8 |

ingredient transmission belt machine |

1 |

Component |

1723 |

1723 |

|

7 |

HQL1500-30-7 |

transmission belt machine |

1 |

Component |

9914 |

9914 |

|

6 |

HQL1500-30-6 |

lower beam |

2 |

A3 |

14182 |

28364 |

|

5 |

HQL1500-30-5 |

main beam |

1 |

A3 |

79826 |

79826 |

|

4 |

HQL1500-30-4 |

reclaiming mechanism |

2 |

Component |

6440 |

12880 |

|

3 |

HQL1500-30-3 |

claw |

2 |

A3 |

1719 |

3439 |

|

2 |

HQL1500-30-2 |

Dolly operation mechanism |

2 |

Component |

7610 |

15200 |

|

1 |

HQL1500-30-1 |

Cart operation mechanism |

4 |

Component |

3348 |

13392 |

|

SN |

code |

Name quantity |

|

Material |

single piece |

total |

remark |

weight |

| |

|

|

|

|

|

���D |

�o(w��)�a���ЙC(j��)�C(j��)е��������˾ |

| |

|

|

|

|

|

| |

|

|

|

|

|

Mark |

̎��(sh��) |

�օ^(q��) |

�����ļ�̖(h��o) |

���� |

������ |

����p��݆�p��ȡ�ϙC(j��) |

�O(sh��)Ӌ(j��) |

�����A |

|

��(bi��o)��(zh��n)�� |

�ǘs�� |

|

�A�Θ�(bi��o)ӛ |

���� |

���� |

�(du��) |

�S��(gu��)(li��n) |

|

���� |

�����t |

|

|

|

|

|

185.6t |

1:50 |

���� |

�X�L(f��ng)Դ |

|

|

|

|

HQL1500-30 |

��ˇ |

Մ���t |

|

Approval |

|

|

�����ڏ� |

|

|

|